Abstract

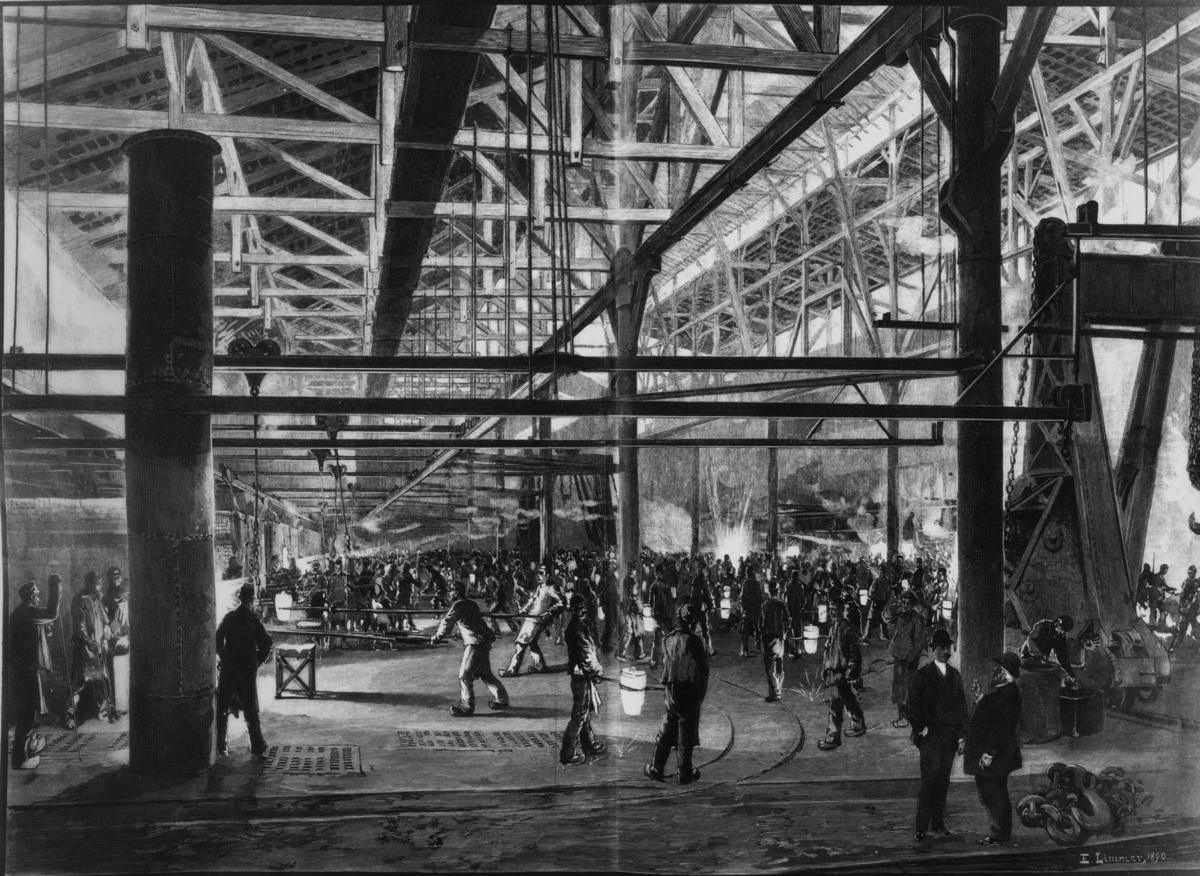

The smelting process and the production of steel ingots weighing as

much as 80 tons, as shown here, required a well-trained and disciplined

workforce. The Krupp enterprise was founded by Friedrich Krupp

(1787–1826), whose oldest son Alfred Krupp (1812–1887) took over sole

proprietorship in 1848. Krupp’s principal products were machinery and

machine components made of high-quality cast steel: equipment for

Germany’s expanding network of railroads (especially the seamless

wheels); artillery for the Prussian military; and later, armored plating

for the German navy. At the time of Alfred Krupp’s death in 1887, his

firm employed more than 20,000 workers. As a

speech included in this volume

suggests, Krupp sought to provide his employees with every incentive to

remain with his firm, including company pensions and subsidized housing.

At the same time, he also adopted a “master of the house” attitude that

brooked no opposition from his “dependents.” This 1890 woodcut is after

a drawing by Emil Limmer.